By Franky Nguyen, AVF Decolletage

Introduction

In precision manufacturing, success is measured in microns.

For industries such as aerospace, automotive, medical, and electronics, the smallest deviation in a component’s dimension can mean the difference between flawless performance and costly failure. That’s why achieving tight tolerances in Swiss CNC machining has become the gold standard for reliability and quality.

At AVF Decolletage, we specialize in producing components with tolerances as tight as ±0.005 mm, ensuring every connector pin, test probe, and screw machine part we manufacture meets exact design specifications.

In this article, we’ll explain what tight tolerances mean, why they matter, and how Swiss CNC machining achieves this unmatched level of precision.

What Does ±0.005 mm Actually Mean?

A tolerance of ±0.005 mm means that a dimension can vary only five microns above or below its intended value — roughly one-tenth the thickness of a human hair.

This level of accuracy ensures that every part fits and functions as intended, without binding, vibration, or electrical failure. In industries where safety, performance, and repeatability are critical, this precision is non-negotiable.

In practical terms:

-

Connector pins must align perfectly for stable electrical contact.

-

Test probes must fit sockets consistently for repeatable measurements.

-

Aerospace fittings must maintain tolerance integrity under thermal expansion.

Learn about our Swiss CNC services

Why Tight Tolerances Are Critical

Tight tolerances aren’t just a technical achievement — they’re a necessity for industries that depend on consistency, safety, and longevity.

✈ Aerospace

In aerospace components, even a slight dimensional variation can lead to vibration, leakage, or mechanical fatigue. Maintaining ±0.005 mm tolerance ensures performance under extreme temperature, pressure, and load.

Medical Devices

Medical instruments and diagnostic components must perform with absolute reliability. Swiss CNC precision ensures smooth operation and compatibility between parts, reducing friction and preventing contamination.

Telecommunications

Signal connectors and RF pins require tight tolerances to ensure consistent contact resistance and signal integrity at high frequencies.

Automotive

Sensors, valves, and control systems rely on precise dimensions for accurate performance and safety. A deviation of even 0.01 mm can affect engine calibration or sensor readings.

Without such precision, product lifespan, reliability, and safety are all compromised.

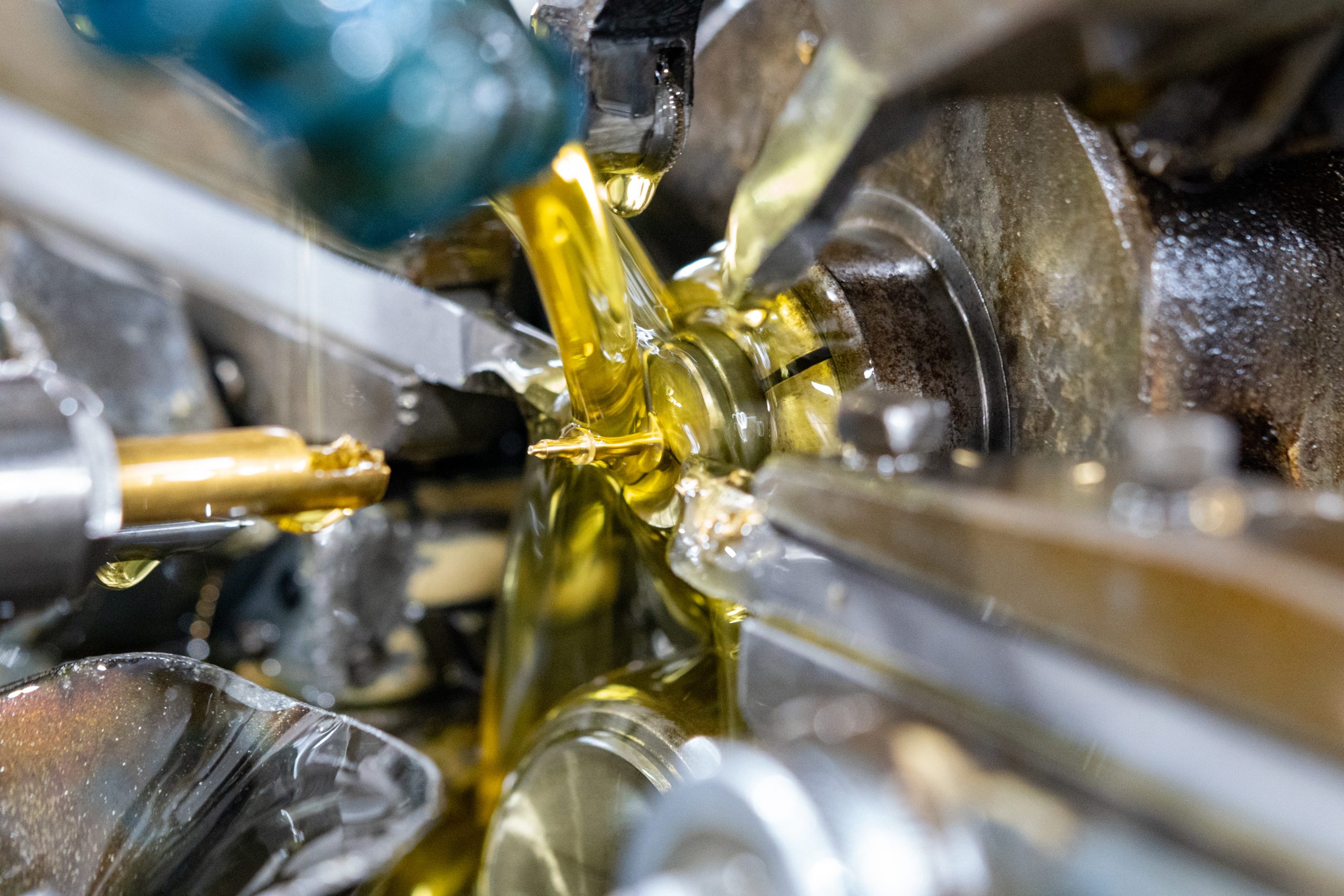

How Swiss CNC Machining Achieves ±0.005 mm

So how does Swiss CNC machining reach tolerances that other processes can’t? It comes down to machine design, process control, and operator expertise.

1️⃣ Guide Bushing Support

Swiss CNC machines use a guide bushing that supports the material close to the cutting zone. This reduces vibration and deflection — key to maintaining consistency in long, slender parts like connector pins.

2️⃣ Multi-Axis Control

Advanced multi-axis capability (up to 12 axes) enables multiple cutting operations in one setup, eliminating alignment errors between processes.

3️⃣ Temperature Stability

Swiss CNC machines operate in thermally controlled environments, preventing metal expansion or contraction that could affect tolerances.

4️⃣ High-Precision Tooling

Tool holders and inserts are engineered for micrometer-level accuracy, ensuring smooth surface finishes and repeatable dimensions.

5️⃣ Burr-Free Finishing

Clean, burr-free finishes are essential in applications like electronics, where sharp edges could affect conductivity or fit.

AVF Decolletage Precision Standards

At AVF Decolletage, precision isn’t just a goal — it’s our daily standard.

We operate a fleet of Star, Tsugami, and Cincom Swiss CNC machines, capable of machining brass, stainless steel, and aluminum to ±0.005 mm tolerances.

Our production floor includes:

-

350+ Swiss CAM and CNC lathes.

-

30+ CNC milling centers.

-

400+ skilled machinists and engineers.

-

ISO 9001:2015-certified quality system.

Every component undergoes rigorous inspection using:

-

Mitutoyo gauges and digital calipers (accuracy 0.001 mm).

-

Keyence optical measurement systems.

-

CMM inspection for complex geometries.

-

XRF coating analysis for plating consistency.

Each production lot is fully traceable, from material certification to final inspection.

Read our ISO 9001:2015 certification

Applications That Depend on ±0.005 mm

Swiss CNC machining at AVF Decolletage supports applications where performance can’t be compromised:

-

Aerospace connectors and valve components.

-

Medical diagnostic equipment and surgical tools.

-

Telecom connectors for high-frequency data transfer.

-

Automotive sensors and fuel injection parts.

-

Micro-mechanical components for instrumentation.

Every one of these products relies on our ability to maintain dimensional control, reduce surface roughness, and guarantee part interchangeability.

Materials That Enable Tight Tolerances

The right material is just as important as the right machine. AVF Decolletage uses only certified materials that perform consistently under Swiss CNC conditions:

-

Brass (C36000, C17300, C54400): Excellent machinability and conductivity.

-

Stainless Steel (303, 316, 416): Superior strength and corrosion resistance.

-

Aluminum (6061, 2017): Lightweight, high-speed machining for large batches.

Each material batch is accompanied by mill test reports (MTRs) and verified before production.

How We Measure and Maintain ±0.005 mm

Achieving tight tolerances is one thing — maintaining them over millions of parts is another.

AVF Decolletage uses real-time process monitoring and in-process inspection to ensure consistency:

-

SPC (Statistical Process Control) monitors dimensional variation.

-

Tool wear tracking maintains accuracy over long production runs.

-

Temperature monitoring compensates for ambient fluctuations.

-

Calibration audits ensure machines meet accuracy standards daily.

This ensures that every shipment — whether 500 or 500,000 parts — meets customer expectations exactly.

Conclusion

When it comes to precision, ±0.005 mm isn’t just a number — it’s a promise.

At AVF Decolletage, we combine Swiss CNC technology, advanced inspection tools, and decades of experience to deliver components that meet the world’s most demanding standards.

Whether it’s a brass connector pin, a stainless-steel test probe, or a high-volume screw machine part, our focus remains the same:

uncompromising accuracy, consistency, and reliability.

When failure is not an option, choose AVF Decolletage — where precision is measured in microns.

Frequently Asked Questions (FAQ)

Q1: Why do industries need tolerances as tight as ±0.005 mm?

Because even a 0.01 mm deviation can affect function, reliability, or safety — especially in aerospace, medical, and electronic parts.

Q2: Can Swiss CNC hold these tolerances in large-scale production?

Yes. AVF Decolletage’s Swiss CNC machines are engineered for continuous, high-volume consistency.

Q3: How does AVF Decolletage measure tolerances this tight?

We use Keyence vision systems, CMM inspection, and Mitutoyo gauges with 0.001 mm accuracy.

Q4: Do all parts require ±0.005 mm precision?

Not all — but we have the capability to achieve it whenever the application demands.

Q5: Which materials achieve this precision best?

Brass, stainless steel, and aluminum — all machined using our Swiss CNC technology.