By Franky Nguyen, AVF Decolletage

Introduction

In the global manufacturing ecosystem, compliance is no longer optional — it’s a foundation of trust.

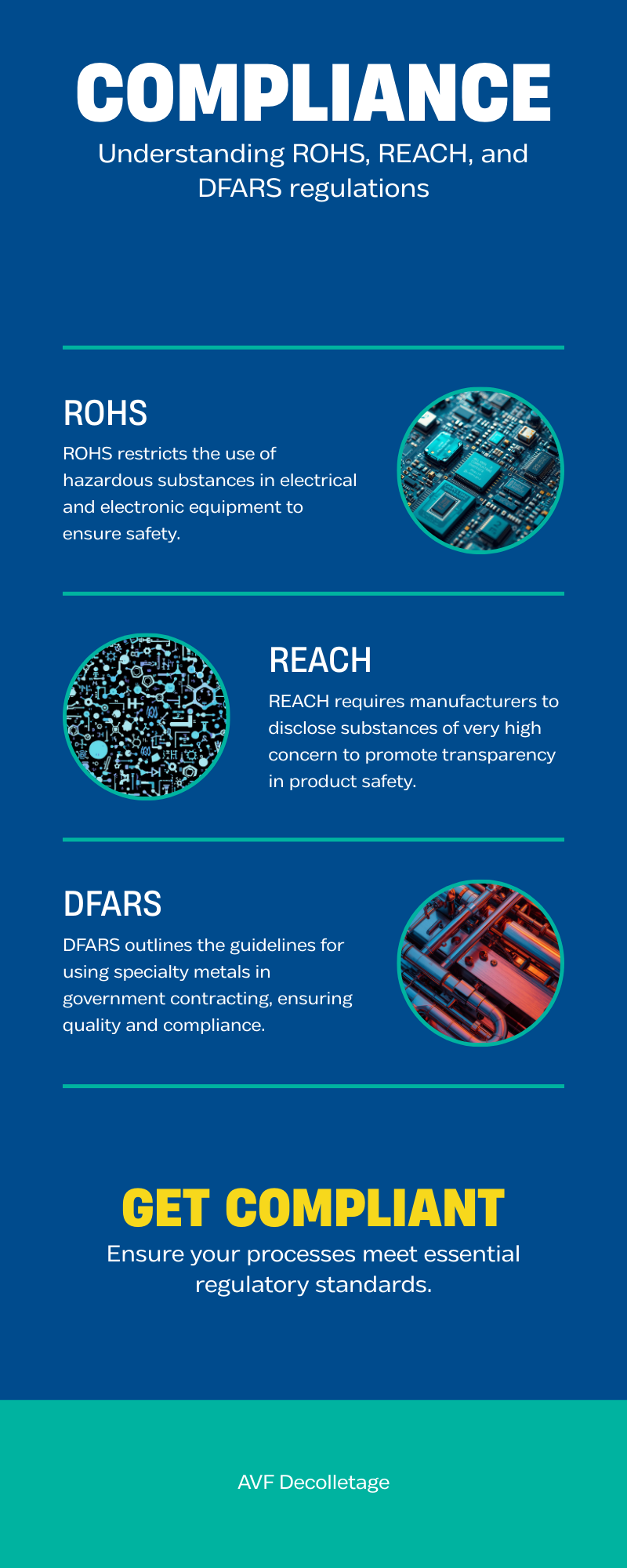

For companies sourcing precision-machined components across borders, understanding key regulatory standards such as ROHS, REACH, and DFARS is essential.

These frameworks don’t just affect documentation — they shape how materials are sourced, how processes are controlled, and ultimately, how safe and sustainable each part is for end use.

At AVF Decolletage, compliance is built into every stage of production — from raw material purchasing to final inspection and export documentation.

This article explains what ROHS, REACH, and DFARS mean, how they apply to precision machining, and how AVF ensures full compliance for customers in aerospace, defense, and high-reliability industries.

👉 Explore AVF Decolletage quality standards: https://avfdecolletage.com/quality-system/

1️⃣ Understanding ROHS — Restriction of Hazardous Substances

ROHS (Directive 2011/65/EU, also known as ROHS 3) originated in the European Union and restricts the use of specific hazardous materials in electrical and electronic equipment.

⚙️ Purpose

The goal is to protect human health and the environment by reducing the presence of toxic elements in manufacturing.

🧪 Restricted Substances

ROHS limits the concentration of the following materials in homogeneous parts to 0.1% (except cadmium at 0.01%):

-

Lead (Pb)

-

Mercury (Hg)

-

Cadmium (Cd)

-

Hexavalent Chromium (Cr⁶⁺)

-

Polybrominated Biphenyls (PBB)

-

Polybrominated Diphenyl Ethers (PBDE)

-

Four types of phthalates (DEHP, BBP, DBP, DIBP)

🧩 What It Means for Precision Machining

Even though machined metal parts aren’t “electronic devices,” they often become components within them.

Therefore, connector pins, housings, and mechanical fittings must comply with ROHS if they’re part of any electrical assembly sold in the EU or U.S. market.

AVF Decolletage ensures ROHS compliance by:

-

Sourcing only certified ROHS-compliant brass, aluminum, and stainless steel materials.

-

Partnering with ROHS-certified plating facilities for nickel, gold, tin, and clear chromate finishes.

-

Maintaining material traceability through supplier declarations and certification storage in our ERP system.

2️⃣ Understanding REACH — Registration, Evaluation, Authorization, and Restriction of Chemicals

REACH (EC 1907/2006) is another EU regulation designed to protect the environment and human health, but it goes beyond simple restriction — it governs the entire lifecycle of chemical substances.

⚙️ Purpose

REACH ensures that manufacturers and importers identify and manage the risks linked to chemicals used in production, including plating, cleaning agents, coolants, and lubricants.

🧪 Key Requirement

Manufacturers must disclose the presence of any Substances of Very High Concern (SVHC) above 0.1% weight by weight.

These include chemicals like:

-

Lead and lead compounds

-

Bisphenol A (BPA)

-

Chromium trioxide

-

Cobalt salts

-

Certain phthalates

🧩 How REACH Affects Machined Components

Even if a machined component is metallic, surface coatings, lubricants, and marking inks may fall under REACH regulations.

AVF Decolletage ensures REACH compliance by:

-

Using REACH-approved plating chemicals and lubricants from qualified suppliers.

-

Requiring REACH declarations from all upstream material providers.

-

Storing Material Safety Data Sheets (MSDS) for each batch.

-

Auditing plating and chemical suppliers annually to verify REACH conformance.

This guarantees that our machined components are safe, sustainable, and ready for export to Europe, North America, and Japan.

3️⃣ Understanding DFARS — Defense Federal Acquisition Regulation Supplement

DFARS (U.S. Department of Defense regulation 252.225-7009) applies to companies supplying parts to U.S. defense and aerospace sectors.

⚙️ Purpose

DFARS ensures that certain critical materials — especially metals — originate from approved U.S. or allied sources to protect national security and supply chain integrity.

🧱 Covered Materials

-

Specialty metals such as steel, titanium, and certain nickel or cobalt alloys.

-

Copper, brass, and aluminum when used in defense-related assemblies.

✈️ DFARS Clause in Practice

For precision machining, this means that raw materials used for defense contracts must come from DFARS-approved mills (typically in the U.S., Canada, or other qualifying countries).

AVF Decolletage ensures DFARS compliance by:

-

Importing DFARS-qualified raw materials (brass, stainless, and aluminum) from certified U.S. and EU suppliers.

-

Maintaining mill certificates with DFARS country-of-origin documentation.

-

Storing lot-level traceability records for every shipment and batch used in aerospace or defense programs.

4️⃣ Why These Regulations Matter to Customers

ROHS, REACH, and DFARS are more than bureaucratic checkboxes — they represent assurance of safety, traceability, and ethical sourcing.

For customers in aerospace, automotive, and electronics industries, these regulations ensure that:

-

Components won’t contaminate systems or cause failures under certification audits.

-

Materials are traceable back to their source — no hidden risk of restricted substances.

-

Suppliers maintain process discipline aligned with global environmental and defense standards.

For AVF Decolletage, compliance isn’t reactive — it’s engineered into every stage of our production flow.

5️⃣ How AVF Decolletage Maintains Global Compliance

✅ Material Control & Traceability

Every raw material batch comes with a mill certificate, heat lot number, and compliance declaration (ROHS, REACH, DFARS).

These are digitally stored and linked to corresponding work orders in our ERP system.

✅ Supplier Qualification & Audits

We only partner with suppliers that provide full documentation and allow audit access.

Plating and finishing partners are regularly inspected for chemical control and waste management under ROHS/REACH.

✅ Internal Training

Our engineers and quality staff undergo annual compliance training covering updates to ROHS and REACH restricted substance lists.

✅ Documentation for Export Customers

For every shipment, AVF provides:

-

Material Certification Report

-

ROHS / REACH Declaration of Conformity

-

DFARS Statement of Material Origin

-

Certificate of Conformance (COC)

6️⃣ Compliance and Sustainability: Two Sides of the Same Coin

ROHS, REACH, and DFARS also reflect AVF’s commitment to sustainability and responsible manufacturing.

By eliminating harmful substances, maintaining clean processes, and ensuring ethical sourcing, we protect not only our customers but also our workforce and environment.

At AVF, sustainability is not an afterthought — it’s integrated into machining, plating, and packaging workflows.

We continue to improve our waste management and metal recycling programs, minimizing the environmental footprint of each component we produce.

Conclusion

In today’s interconnected manufacturing world, compliance is precision.

Every part leaving a supplier’s dock represents the integrity of a global supply chain — and non-compliance can jeopardize far more than a single order.

By adhering to ROHS, REACH, and DFARS, AVF Decolletage gives its customers complete peace of mind:

Every part is safe, traceable, and qualified for use in the most demanding industries on earth.

Because true precision doesn’t stop at dimensions — it extends to the standards behind them.

👉 View our compliance certificates: https://avfdecolletage.com/reach/

👉 View our compliance certificates: https://avfdecolletage.com/rohs/

👉 Request documentation or RFQ: https://avfdecolletage.com/request-for-quote/

Frequently Asked Questions (FAQ)

Q1: What’s the difference between ROHS and REACH?

ROHS restricts specific hazardous materials in electrical components. REACH focuses on chemical safety throughout the manufacturing lifecycle.

Q2: Do all AVF products comply with ROHS and REACH?

Yes. All materials and finishes used by AVF Decolletage are ROHS and REACH compliant, verified through supplier declarations and audits.

Q3: What if my parts are for a U.S. defense program?

AVF can provide DFARS material certificates confirming the raw material originates from approved sources.

Q4: Can you provide documentation with each shipment?

Absolutely. Each lot includes a Material Certificate, ROHS/REACH Declaration, and Certificate of Conformance for traceability.

Q5: How often are compliance standards updated?

The EU updates ROHS and REACH substance lists every 6–12 months. AVF reviews all supplier declarations quarterly to stay current.