By Franky Nguyen, AVF Decolletage

Reduce CNC Machining Cost — Introduction

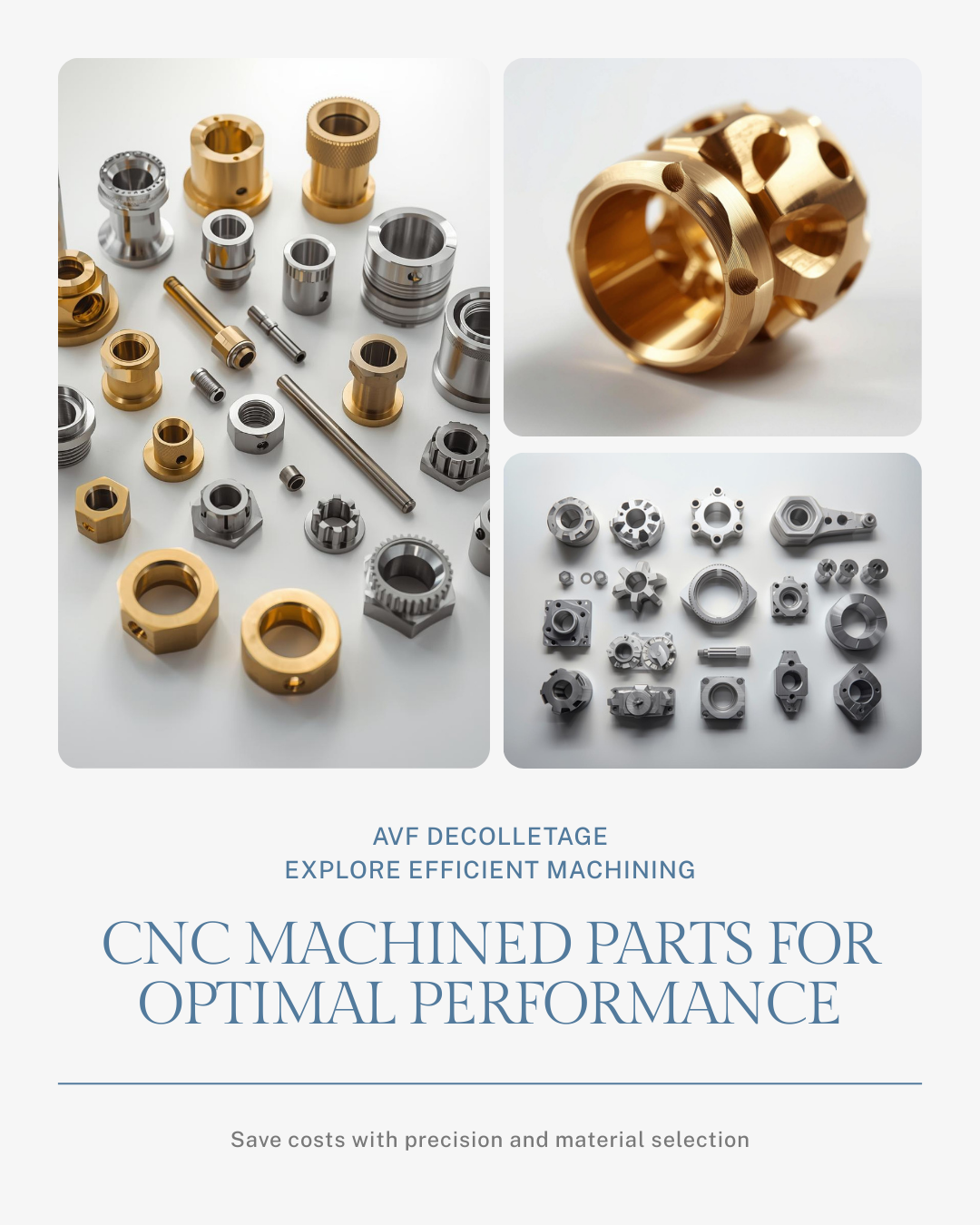

To Reduce CNC Machining Cost, the most important strategy is improving the part design before production even begins. At AVF Decolletage, we manufacture millions of parts every year — connector pins, sockets, terminals, inserts, bushings, micro-precision parts — and we consistently see that smart design choices can cut machining cost by 20–60%.

In this complete engineering guide, you’ll learn the 10 most effective methods to reduce CNC machining cost while improving manufacturability, precision, consistency, and lead time.

Table of Contents

-

What Affects CNC Machining Cost?

-

How Material Selection Helps Reduce CNC Machining Cost

-

How Tight Tolerances Increase CNC Machining Cost

-

Standardizing Diameters to Reduce CNC Machining Cost

-

Removing Features That Increase CNC Machining Cost

-

Reducing CNC Machining Cost by Minimizing Secondary Operations

-

Optimizing Machining Stroke & Part Length

-

Threading Choices to Reduce CNC Machining Cost

-

Chamfers vs Radii — Cost Impact

-

Avoiding Thin Walls to Reduce CNC Machining Cost

-

Correct Case Studies From AVF Decolletage

-

Summary Table

-

Final Recommendations

-

Q&A

-

References

1. What Affects CNC Machining Cost?

Key cost drivers:

-

Machining cycle time

-

Tool wear and tool changes

-

Material machinability

-

Scrap/reject rate

-

Secondary operations

-

Part handling

-

Setup time

-

QA inspection

-

Machine type (Swiss CNC is most efficient for small parts)

The faster the machine cuts, the lower the cost.

The simpler the geometry, the faster the cycle time.

2. How Material Selection Helps Reduce CNC Machining Cost

Material selection has a huge impact on:

-

Cycle time

-

Tool life

-

Surface finish

-

Chip formation

-

Burr level

-

Scrap

-

Overall cost

✔ Cost-efficient materials

-

Brass C36000 (best machinability)

-

Aluminum A6061 / A2011

-

Stainless Steel 303

-

Free-machining steels (12L14 / 12L15)

❌ High-cost-to-machine materials

-

Stainless Steel 304 / 316

-

Pure copper C11000 (gummy)

-

Beryllium copper C17300 (hard on tools)

-

Phosphor bronze C54400

Design Tip

Choose the most machinable material that still meets your performance requirements — one of the fastest ways to Reduce CNC Machining Cost.

3. How Tight Tolerances Increase CNC Machining Cost

Every 0.01 mm of tolerance affects:

-

Feed rate

-

Tool pressure

-

Heat generation

-

Burr formation

-

QA time

-

Scrap

Cost escalation from tightening tolerances:

| Tolerance | Cost Impact |

|---|---|

| ±0.10 mm | Baseline |

| ±0.05 mm | +10–20% |

| ±0.02 mm | +30–50% |

| ±0.01 mm | +80–120% |

| ±0.005 mm | +200–400% |

Tight tolerances should be used only where critical.

4. Standardizing Diameters to Reduce CNC Machining Cost

Every diameter step means:

-

New cutting tool

-

Speed change

-

Feed change

-

Increased cycle time

❌ Poor design

Ø2.40 → Ø2.10 → Ø1.80 → Ø1.50 → Ø1.20

✔ Optimized design

Ø2.40 → Ø1.80 → Ø1.20

This reduces cycle time and improves consistency.

5. Removing Features That Increase CNC Machining Cost

Certain features drastically slow down machining:

-

Deep holes (3–10× diameter)

-

Internal undercuts

-

Ultra-small radii (<0.2 mm)

-

Sharp internal corners

-

Complex grooving

If a feature does not impact function → remove it.

6. Reduce CNC Machining Cost by Minimizing Secondary Operations

Secondary ops are very expensive:

-

Slotting

-

Milling flats

-

Cross holes

-

Knurling

-

Hand deburring

-

Re-chucking

-

Tapping in a second setup

✔ Goal

Design parts to be completed in one operation on Swiss CNC machines.

7. Optimizing Machining Stroke & Part Length

Long parts require:

-

More guide-bushing engagement

-

Lower feed rates

-

More rigidity

-

Additional tool passes

Practical guideline

-

Length >4× diameter → cycle slows

-

Length >10× diameter → major slowdown

Shorten length if possible to reduce CNC machining cost.

8. Threading Choices to Reduce CNC Machining Cost

Custom threads require:

-

Custom inserts

-

Slower cutting

-

Special gauges

✔ Use standard threads

-

Metric: M2 / M2.5 / M3 / M4 / M5

-

UNC / UNF

-

4-40, 6-32, 8-32

Standard threads = lower cost + faster machining.

9. Chamfers vs Radii — Cost Impact

⭐ Chamfers

-

Fast

-

Simple

-

No special tools

❗ Radii

-

Require interpolation

-

Slower feed rates

-

Need custom tooling

Use chamfers unless radii are critical to function.

10. Avoid Thin Walls to Reduce CNC Machining Cost

Thin walls cause:

-

Chatter

-

Vibration

-

Distortion

-

Tool pressure marks

-

Scrap

Recommended minimum wall thickness:

-

1.0 mm for metal parts

-

0.5 mm for small brass/aluminum components

11. Case Studies From AVF Decolletage

✔ Case Study 1: Connector Pin (Diameter Standardization)

Original Design:

-

5 stepped diameters (Ø2.40 → Ø2.10 → Ø1.80 → Ø1.50 → Ø1.20)

-

3 tools

-

22.5 sec cycle time

Optimized Design:

-

3 stepped diameters (Ø2.40 → Ø1.80 → Ø1.20)

-

Fewer tool changes

-

17.2 sec cycle time

Savings:

✔ 24% faster machining

✔ 18% cost reduction

✔ Case Study 2: Stainless Steel Socket Contact (Material Optimization)

Original Material: S.S. 304

-

Poor chip break

-

High burrs

-

31 sec cycle time

Optimized Material: S.S. 303

-

Cleaner chips

-

Better finish

-

22 sec cycle time

Savings:

✔ 29% faster machining

✔ 21% cost reduction

✔ Case Study 3: Aluminum Micro-Component (Tolerance Optimization)

Original:

-

±0.01 mm everywhere

-

±0.02 mm OAL

-

12.8 sec cycle

-

5% scrap

Optimized:

-

Only two critical dims at ±0.01 mm

-

Others relaxed to ±0.05 mm

-

9.4 sec cycle

-

Scrap <1%

Savings:

✔ 26% faster

✔ 22% cheaper

12. Summary Table

| Cost Driver | Impact | Recommendation |

|---|---|---|

| Tight tolerances | High | Loosen non-critical |

| Too many diameters | High | Standardize sizes |

| Tough materials | High | Pick machinable alloy |

| Deep holes | High | Reduce depth |

| Undercuts | High | Avoid |

| Secondary ops | Very High | One-setup machining |

| Thin walls | High | Increase wall thickness |

| Custom threads | Medium | Use standard |

| Radii | Medium | Use chamfers |

13. Final Recommendations

To Reduce CNC Machining Cost, the most effective methods include:

✔ Use machinable materials

✔ Avoid over-tight tolerances

✔ Standardize diameters

✔ Remove unnecessary features

✔ Avoid deep holes and undercuts

✔ Minimize secondary operations

✔ Design for one-process machining

✔ Ask AVF for free DFM review

Request a Quote: https://avfdecolletage.com/request-for-quote/

14. Q&A

Q1: What reduces CNC machining cost the most?

Standardizing diameters + relaxing tolerances.

Q2: Is Swiss CNC turning cheaper?

Yes — for small precision parts, it’s the most efficient.

Q3: Do materials impact machining cost?

Absolutely. Brass C36000 and Aluminum 6061 are the fastest to machine.