By Franky Nguyen, AVF Decolletage

Introduction

Connector Pins and Sockets are among the most important components in modern electronics. They establish the secure and reliable pathways for power and data. Without connector pins and sockets, critical systems in aerospace, automotive, medical, telecommunications, and defense would not function.

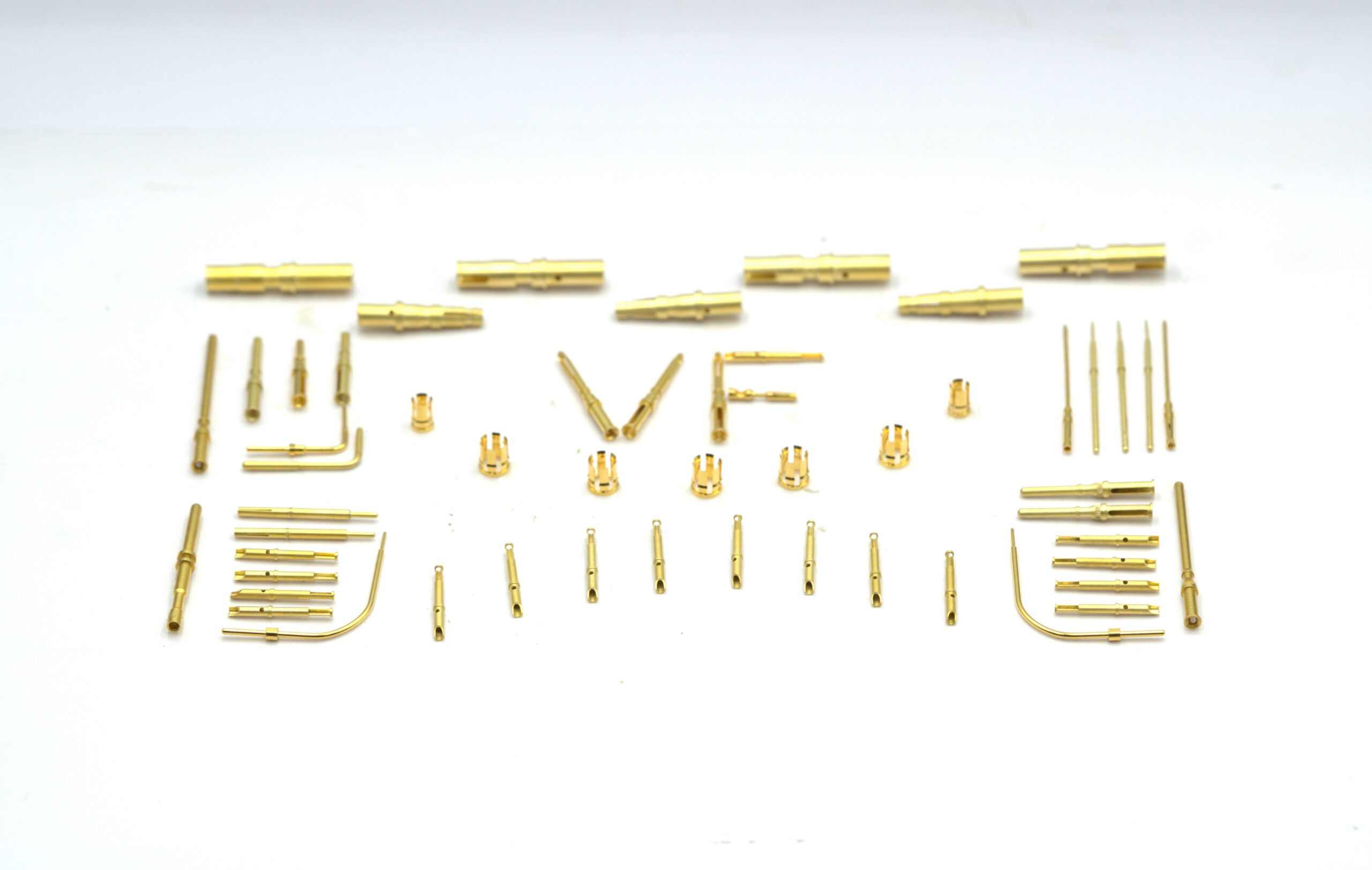

At AVF Decolletage, we manufacture connector pins and sockets from brass, stainless steel, and aluminum using Swiss CNC and CAM machining. With tolerances as tight as ±0.005 mm, our precision parts are trusted worldwide.

This article explores the top five industries that rely most on connector pins and sockets, explaining why they are essential and how AVF Decolletage ensures performance.

1. Connector Pins and Sockets in Aerospace

Aerospace systems must operate flawlessly. Connector pins and sockets are critical in:

-

Avionics systems.

-

Communication modules.

-

Navigation and radar equipment.

-

Flight data recorders.

Because aircraft face extreme conditions such as vibration, pressure changes, and high or low temperatures, connector pins and sockets must guarantee stability. Precision machining and high-quality plating (often gold or nickel) ensure durability in these harsh environments.

Case Example: AVF Decolletage supplied aerospace customers with gold-plated brass connector pins for communication systems. These parts maintained conductivity despite constant vibration and long service cycles.

Learn about our aerospace-grade quality system.

2. Connector Pins and Sockets in Automotive Electronics

Today’s vehicles depend on electronics as much as mechanics. From electric vehicles to hybrid models, connector pins and sockets ensure seamless data and power transfer across:

-

Engine Control Units (ECUs).

-

Safety systems such as ABS and airbags.

-

Infotainment and navigation.

-

Electric vehicle charging systems.

Automotive connectors must resist vibration, oil, and thermal stress. Brass pins plated with tin or nickel are commonly used. For EV charging, high-current connectors with gold plating are often preferred to minimize resistance.

Case Example: An EV manufacturer worked with AVF Decolletage to design tin-plated brass charging pins. These connectors endured thousands of mating cycles while maintaining low contact resistance.

See our automotive and motorcycle parts services.

Precision connector pins and sockets from AVF Decolletage serve aerospace, automotive, medical, telecom, and defense industries.

3. Connector Pins and Sockets in Medical Devices

In the medical field, reliability can mean the difference between life and death. Connector pins and sockets are vital in medical electronics, including:

-

Patient monitoring systems.

-

Surgical instruments.

-

Diagnostic imaging machines.

-

Implantable devices.

Medical connectors must meet strict standards. They require biocompatibility, corrosion resistance, and high conductivity. AVF Decolletage often uses stainless steel (316) or gold-plated brass for medical connectors.

Case Example: For a patient monitoring device, we manufactured gold-plated C17300 BeCu pins. These ensured conductivity and provided the spring properties needed for repeated use.

4. Connector Pins and Sockets in Telecommunications

Modern communication networks run on high-speed, low-loss connections. Connector pins and sockets support everything from fiber optics to 5G.

Applications include:

-

Data centers.

-

Networking hardware.

-

Fiber optic connectors.

-

High-frequency RF systems.

To ensure stability, connectors must minimize signal loss. Brass pins with gold or nickel plating are often used in telecom because they balance cost with conductivity.

Case Example: AVF Decolletage produced fine-pitch brass pins for a telecom OEM. These parts maintained performance at high frequencies, ensuring reliable 5G data transmission.

5. Connector Pins and Sockets in Defense and Military

The defense industry operates in the toughest environments. Connectors must survive shock, vibration, moisture, and sand exposure. Connector pins and sockets are used in:

-

Military radios.

-

Navigation and targeting systems.

-

Tactical vehicles.

-

Drones and missile guidance systems.

Military connectors often follow MIL-DTL standards and require heavy-duty plating such as nickel for corrosion resistance.

Case Example: AVF Decolletage manufactured nickel-plated brass pins for desert operations. These connectors resisted corrosion and abrasion while meeting military specifications.

See our material certification samples.

Conclusion

From aerospace to defense, connector pins and sockets are the foundation of reliable electronics. Each industry requires different materials, coatings, and tolerances, yet they all share one expectation: consistent performance under pressure.

At AVF Decolletage, we combine Swiss machining technology, ISO 9001:2015 certification, and premium materials to deliver connector pins and sockets trusted across the world.

FAQ

Q1: Which industries rely most on connector pins and sockets?

Aerospace, automotive, medical, telecommunications, and defense.

Q2: Why do aerospace connectors often use gold plating?

Because gold provides the best conductivity and corrosion resistance in extreme conditions.

Q3: What materials are used in medical connectors?

Stainless steel (316) and gold-plated brass are common for their durability and biocompatibility.

Q4: Can AVF Decolletage make custom connector pins and sockets?

Yes, we design and manufacture both standard and custom solutions.

Q5: What tolerances can AVF Decolletage achieve?

We machine down to ±0.005 mm using Swiss CNC and CAM technology.