By Franky Nguyen, AVF Decolletage

Introduction

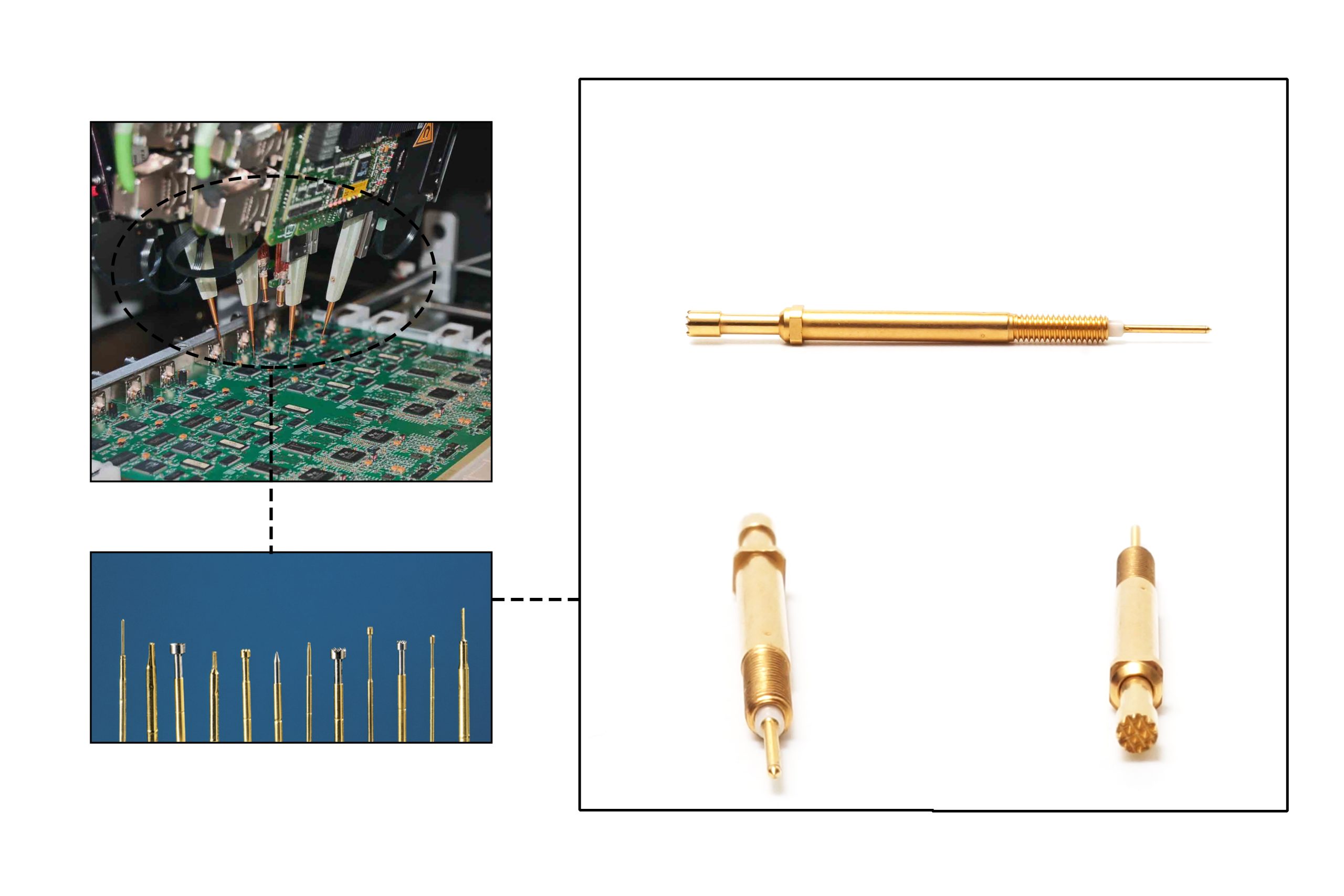

In the world of electronics testing, test probes are indispensable. They establish the temporary electrical connections needed to verify circuit performance, ensuring that devices function reliably before reaching the market.

But when production reaches millions of units, material choice becomes critical. Brass is the go-to material for high-volume test probes because it combines conductivity, machinability, durability, and cost-efficiency.

At AVF Decolletage, we specialize in manufacturing brass test probes with Swiss CNC machining and ISO-certified inspection processes — making them ideal for industries that demand both performance and scale.

Why Brass Is Ideal for Test Probes

Brass offers unique advantages over other materials such as copper, stainless steel, or aluminum:

-

Excellent Conductivity – Enables accurate signal transmission during testing.

-

Superior Machinability – Brass can be machined with high precision and tight tolerances.

-

Durability – Withstands repeated contact cycles without losing performance.

-

Corrosion Resistance – Prevents oxidation, ensuring consistent readings.

-

Cost Efficiency – More economical than other alloys, especially in mass production.

High-Volume Manufacturing Advantages

When producing probes in the millions, efficiency is everything. Brass supports:

-

High-Speed Machining – Reduced cycle times on Swiss CAM machines.

-

Consistency Across Millions of Parts – Tight tolerances maintained batch after batch.

-

Lower Production Costs – Allowing competitive pricing for global OEMs.

Applications of Brass Test Probes

Brass test probes are widely used in:

-

Electronics Manufacturing – PCB and semiconductor testing.

-

Automotive Electronics – ECU and sensor validation.

-

Telecommunications – 5G and RF device testing.

-

Consumer Devices – Smartphones, laptops, and wearables.

Plating Options for Brass Probes

To further improve performance, brass probes are often plated with:

-

Gold – Enhances conductivity and resists oxidation.

-

Nickel – Adds durability and wear resistance.

-

Tin – A cost-effective option for certain applications.

At AVF Decolletage, we provide plating certifications with every batch.

See our material certification samples.

Why AVF Decolletage for Brass Test Probes?

-

Scale: High-volume production with Swiss CAM machines.

-

Precision: CNC machining for custom probes with tight tolerances.

-

Certifications: ISO 9001:2015, RoHS, and REACH compliance.

-

Experience: Decades of supplying connectors and probes to global OEMs.

Conclusion

Brass test probes are the backbone of high-volume electronics testing. They combine conductivity, durability, and cost-effectiveness, making them the material of choice for OEMs across industries.

At AVF Decolletage, we manufacture brass test probes at scale with Swiss machining precision and ISO-certified inspection, ensuring every probe meets the highest standards.

FAQ

Q1: Why is brass used instead of copper for test probes?

Brass offers similar conductivity but is stronger and easier to machine.

Q2: How many cycles can brass test probes last?

With plating, brass probes can withstand thousands of contact cycles.

Q3: Are brass probes suitable for RF testing?

Yes, when gold plated, brass probes are excellent for RF applications.

Q4: Can AVF Decolletage produce millions of probes?

Yes, we specialize in high-volume CAM production.

Q5: Do you provide plating certifications?

Yes, every batch includes plating and material certificates.