By Franky Nguyen, AVF Decolletage

Introduction

In today’s fast-moving manufacturing world, companies face increasing pressure to deliver products that are not only high-performing but also cost-efficient and globally competitive. The demand for precision-machined components — from connector pins to test probes and micro parts — continues to grow across industries such as aerospace, automotive, and electronics.

At AVF Decolletage, we understand that precision, quality, and reliability are not optional — they’re essential. For over two decades, we’ve built a reputation as a global partner in precision machining, offering unparalleled expertise in Swiss CNC and CAM technology.

From our manufacturing headquarters in Vietnam to our customer support office in Virginia, USA, we serve clients across North America, Europe, and Asia, providing end-to-end machining solutions that meet the most demanding technical and logistical requirements.

The AVF Decolletage Advantage

What sets AVF Decolletage apart is our ability to combine Swiss precision, Asian scalability, and American customer service into a single seamless experience.

Our philosophy is simple: precision without compromise.

We don’t just manufacture components — we engineer reliability. Every connector pin, socket, test probe, and screw machine part that leaves our facility undergoes meticulous inspection and documentation to ensure consistent performance, lot after lot.

We take pride in being more than a supplier — we are a strategic partner trusted by global OEMs for long-term collaboration and product excellence.

Our Capabilities

At the heart of AVF Decolletage’s success lies an investment in cutting-edge technology, skilled craftsmanship, and continuous improvement.

-

350+ Swiss CAM and CNC lathes (Bechler, Tornos, Star, Tsugami, Cincom).

-

30+ CNC milling centers for complex, multi-axis parts.

-

400+ experienced employees, including machinists, QC inspectors, and engineers.

-

ISO 9001:2015 certification, ensuring global quality compliance.

-

Tolerances up to ±0.005 mm, enabling micro-level precision for mission-critical parts.

This advanced production capacity allows us to serve high-volume programs for electronics and automotive industries while maintaining the tightest tolerances required for aerospace and medical applications.

Explore our machining services

The Manufacturing Process: Precision from Start to Finish

At AVF Decolletage, every component’s journey — from raw material to finished part — follows a well-defined and ISO-controlled process.

1️⃣ Material Selection

We start by sourcing certified materials from global suppliers.

Brass (C36000, C17300, C54400, C19160), stainless steel (303, 316, 416), and aluminum (6061, 2017) are commonly used depending on conductivity, corrosion resistance, or strength requirements.

Each batch undergoes chemical verification and material certification review before entering production.

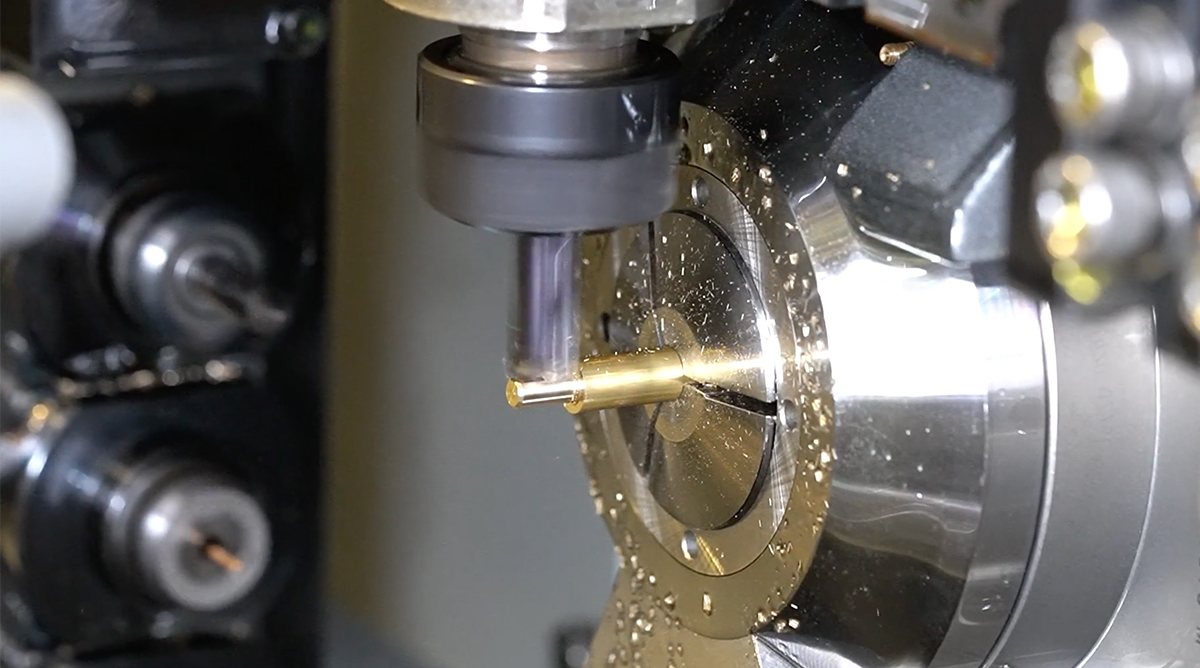

2️⃣ Swiss CAM & CNC Machining

Our dual approach — combining Swiss CAM for speed and Swiss CNC for complexity — allows us to achieve high precision at competitive cost.

-

Swiss CAM delivers high-speed production for simpler geometries like connector pins and spacers.

-

Swiss CNC handles complex profiles, threads, and slots with precision up to ±0.005 mm.

This hybrid production model gives customers the best of both worlds — efficiency and flexibility.

3️⃣ Secondary Processes and Finishing

Machining is just the beginning. We add value through in-house secondary operations, ensuring every component meets its final functional and cosmetic requirements.

-

Threading, drilling, slotting, and bending.

-

Heat treatment for strength and wear resistance.

-

Gold, nickel, tin, or silver plating for conductivity and corrosion protection.

-

Surface finishing and polishing for aesthetic appeal.

Every process follows RoHS and REACH standards to meet international compliance.

See our material certification samples

4️⃣ Quality Control and Inspection

Precision without verification is incomplete.

That’s why AVF Decolletage employs a multi-layered inspection process supported by advanced measuring technology:

-

CMM (Coordinate Measuring Machine) for dimensional verification.

-

Mitutoyo calipers and gauges with 0.001 mm accuracy.

-

Keyence vision inspection for automated optical analysis.

-

Microscopic surface checks (10X–40X magnification).

-

XRF coating analysis for plating consistency.

Each production batch includes First Article Inspection (FAI), in-process inspection, and final approval reports — all documented under our ISO 9001:2015 system.

Learn more about our quality system

5️⃣ Packaging & Logistics

Every order is packaged with precision as well. Parts are cleaned, protected with anti-corrosion film, and sealed with full lot traceability.

With manufacturing in Vietnam and a U.S. logistics hub in Virginia, AVF Decolletage supports global customers through flexible EXW, FOB, or DAP shipping terms.

Products We Deliver

Our diverse product portfolio meets the needs of multiple industries and technologies:

-

Connector Pins & Sockets: Engineered for stable electrical connections and low contact resistance.

-

Test Probes: Ensuring repeatable accuracy in electronic testing and measurement.

-

Screw Machine Products: Providing cost-effective precision for large-scale assemblies.

-

Custom Machined Components: Designed to meet specific customer drawings and tolerances.

Each category benefits from our ability to customize geometry, material, plating, and packaging according to customer requirements.

Industries We Serve

Our products are found in a variety of high-performance applications:

-

Aerospace & Defense: Flight-critical components built for extreme conditions.

-

Automotive & Motorcycle: High-volume precision parts for sensors, engines, and safety systems.

-

Medical Devices: Safe, clean, and consistent parts for diagnostic and surgical tools.

-

Telecommunications & Data: High-speed connectors and signal components.

-

Electronics & Consumer Goods: Compact precision parts for reliable connectivity.

Why Choose AVF Decolletage?

Customers choose AVF Decolletage for more than just precision — they choose us for partnership, performance, and trust.

-

Scalable Production: From prototypes to millions of parts per year.

-

Competitive Pricing: Efficiency from Swiss CAM & CNC hybrid machining.

-

Global Reach: Serving OEMs in North America, Europe, and Asia.

-

Complete Traceability: Full documentation from raw material to shipment.

-

Customer Collaboration: We work closely with engineering teams to optimize designs and reduce cost.

Our long-term partners stay with us because we solve problems, deliver consistency, and help them grow.

Commitment to Innovation & Sustainability

At AVF Decolletage, innovation and responsibility go hand in hand.

We continuously invest in:

-

Automation to increase throughput and precision.

-

AI-driven inspection systems to detect anomalies faster.

-

Chip and coolant recycling to minimize environmental impact.

-

Energy-efficient equipment that supports green manufacturing.

Our approach ensures both technological excellence and sustainability, allowing us to meet customer demands while protecting the planet.

Conclusion

For more than 25 years, AVF Decolletage has been more than a manufacturer — we’ve been a trusted global partner for precision machining excellence.

Our connector pins, test probes, screw machine parts, and custom machined components form the backbone of modern technology. Through Swiss engineering, ISO-certified quality, and a customer-first approach, we continue to deliver products that power the future — one micron at a time.

When precision, reliability, and scalability matter, AVF Decolletage delivers.

Frequently Asked Questions (FAQ)

Q1: What makes AVF Decolletage unique?

Our ability to blend Swiss precision with large-scale production — ensuring quality, speed, and affordability.

Q2: Which industries rely on your components?

Aerospace, automotive, medical, electronics, and defense.

Q3: Can you handle both prototype and mass production?

Yes. We specialize in flexible production that scales from R&D samples to full runs.

Q4: How do you ensure quality?

Through ISO 9001:2015 certification, advanced QC tools, and highly trained personnel.

Q5: Where do you ship your products?

Worldwide — with customers across the U.S., Europe, and Asia.